Optical Fibre Diameter Analyser vs. Traditional Methods: Which is More Reliable?

Optical Fibre Diameter Analyser vs. Traditional Methods: Which is More Reliable?

Blog Article

Understanding the Capability of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser offers as a pivotal instrument in modern-day production, supplying accurate, non-contact measurements that are vital for keeping rigid market requirements. By leveraging sophisticated laser innovation, these analysers not only make sure marginal signal loss however also boost the general efficiency of optical fibres.

Relevance of Optical Fibre Dimension

In contemporary manufacturing, the dimension of optical Fibre Diameter is crucial for ensuring the performance and integrity of Fibre optic systems. Accurate Diameter dimension directly influences optical efficiency, as variants can result in boosted signal loss, minimized data transfer, and lessened total performance. The optical buildings, including light transmission and signal stability, are very conscious the Fibre's Diameter, demanding exact control during manufacturing.

Moreover, standardization in Fibre Diameter is vital for compatibility and interoperability within varied telecommunications networks. As these networks increase worldwide, preserving uniformity in Fibre qualities promotes smooth combination throughout numerous components and systems. Furthermore, adhering to industry requirements worrying Diameter tolerances is vital for manufacturers to meet regulative requirements and consumer assumptions.

Spending in innovative dimension modern technologies not just boosts manufacturing efficiency but additionally supports top quality assurance procedures, making it possible for suppliers to identify defects early in production. This positive technique decreases waste and makes sure that the last products satisfy rigid performance requirements. The significance of optical Fibre measurement can not be overstated, as it offers as a structure for high-quality, reputable Fibre optic systems, which are indispensable to modern communication facilities.

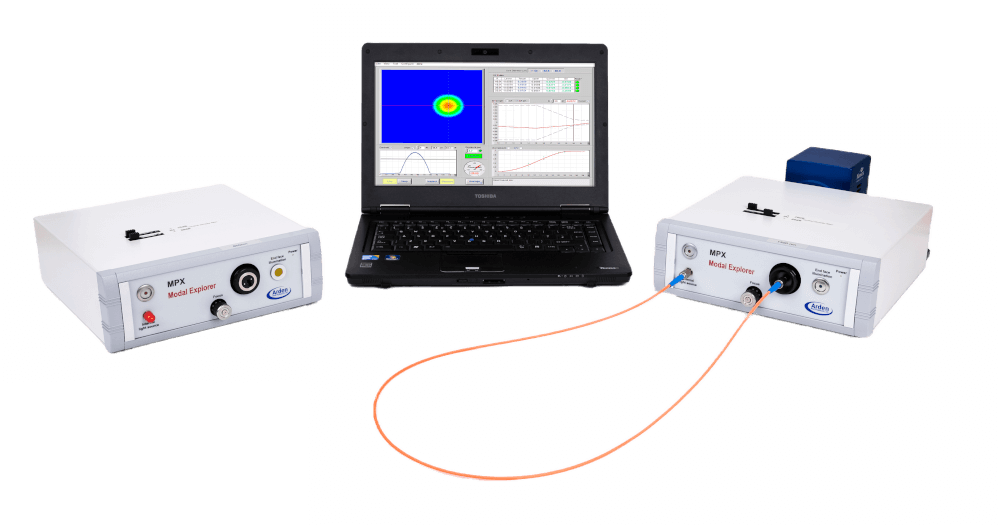

Exactly How Diameter Analysers Job

The core operation relies on the concept of light spreading and reflection. As the laser beam strikes the Fibre, variations in Diameter cause adjustments in the light's intensity and wavelength (optical fibre diameter analyser). This information is refined in real-time utilizing sophisticated formulas that convert the optical signals right into exact Diameter measurements

Additionally, several Diameter analysers are equipped with numerous dimension factors along the Fibre, enabling for a detailed evaluation of Diameter uniformity. The implementation of such innovation significantly boosts quality control in production, ensuring that optical fibres are generated to exact specs for optimal performance in their desired applications.

Secret Features to Take Into Consideration

When picking an optical Fibre Diameter analyser, several crucial functions call for mindful factor to consider to guarantee optimum efficiency and dependability. Dimension precision is paramount; the analyser should supply precise Diameter analyses, typically in micrometers, to satisfy stringent manufacturing specs. In addition, a large dimension variety boosts flexibility, suiting different Fibre types and densities.

Another essential attribute is the analyser's speed. Rapid measurement capabilities permit for enhanced throughput, important in high-volume production settings. Real-time data processing and comments capabilities enable immediate adjustments, enhancing quality control.

Interface and software program compatibility are also substantial factors to consider. An easy to use interface enhances procedure, while robust software program support promotes information look these up evaluation and integration with existing manufacturing systems. The capability to export information in different layouts can boost coverage and conformity efforts.

In addition, sturdiness and maintenance needs must be reviewed. An analyser built from top notch products will hold up against the rigours of a manufacturing setting, while ease of upkeep guarantees long life and decreases downtime. Finally, take into consideration the degree of technological support and training given by the supplier, as this can dramatically impact the effective use the analyser in production setups.

Advantages in Production Efficiency

Enhancing manufacturing efficiency rests on the combination of advanced modern technologies, such as optical Fibre Diameter analysers. These tools play a pivotal role in making certain that optical fibers meet stringent high quality criteria, which is important for optimum performance in various applications - optical fibre diameter analyser. By giving real-time measurements of Fibre Diameter, makers can quickly identify and correct inconsistencies from specified resistances, thus decreasing waste and decreasing the danger of defective items

Furthermore, the early detection of prospective problems leads to decreased downtime and maintenance costs, therefore maximizing source appropriation. Inevitably, the efficiency obtains recognized with using optical Fibre Diameter analysers add to an extra affordable production setting, making certain that companies can provide top notch products while preserving cost-effectiveness and responsiveness to market demands.

Applications Across Industries

The flexibility of optical Fibre Diameter analysers extends past making effectiveness, locating applications throughout numerous sectors that rely on optical Fibre modern technology. In telecoms, these analysers are vital for making sure the ideal efficiency of Fibre optic cords, straight influencing information transmission rates and network integrity. By precisely measuring Fibre sizes, drivers can decrease signal loss and enhance general communication quality.

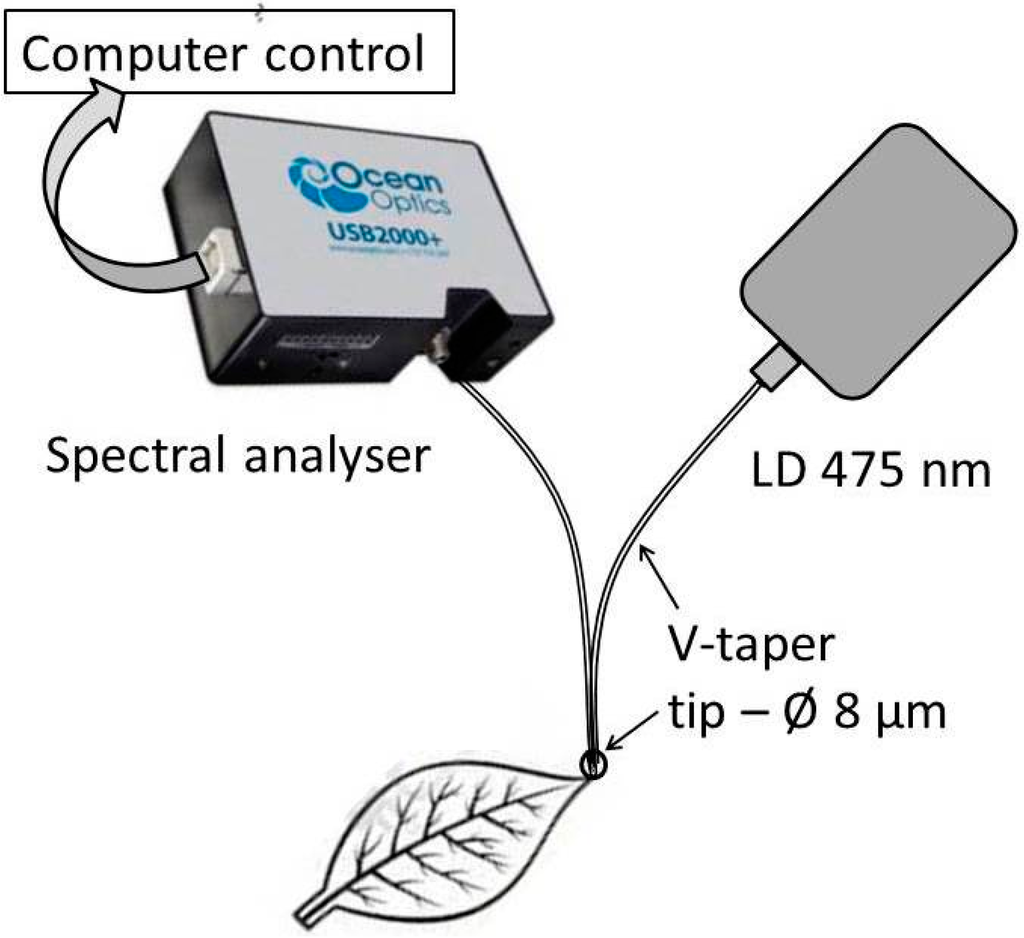

The clinical important source sector additionally profits significantly from these devices, specifically in the growth of endoscopic devices and laser therapies. Accurate Diameter dimensions are vital for producing reliable optical fibers that are utilized in minimally invasive procedures, enhancing client outcomes with enhanced imaging and therapy capabilities.

In aerospace, the analysers play an essential duty in the production of lightweight, high-strength materials, where Fibre optics are integrated into architectural parts for tracking and diagnostics. In addition, the automotive sector uses these gadgets to guarantee the honesty of Fibre optic sensors that improve safety and performance functions in lorries.

Verdict

In final thought, the optical Fibre Diameter analyser is essential for modern manufacturing, ensuring specific dimensions that copyright market criteria. Its innovative laser modern technology and real-time information handling abilities improve quality assurance and functional effectiveness. By automating the dimension procedure, producers can swiftly spot deviations, consequently minimizing signal loss and manufacturing downtime. The diverse applications throughout various markets underscore the analyser's relevance in promoting continuous improvement and data-driven decision-making within the manufacturing industry (optical fibre diameter analyser).

In contemporary manufacturing, the measurement of optical Fibre Diameter is crucial for making check out this site certain the performance and reliability of Fibre optic systems. The relevance of optical Fibre measurement can not be overemphasized, as it serves as a foundation for top notch, dependable Fibre optic systems, which are important to modern communication framework.

Diameter analysers utilize advanced optical technologies to properly measure the Diameter of optical fibres.Additionally, lots of Diameter analysers are equipped with numerous dimension points along the Fibre, permitting for an extensive evaluation of Diameter consistency.The versatility of optical Fibre Diameter analysers prolongs beyond producing effectiveness, locating applications across various markets that rely on optical Fibre modern technology.

Report this page